Each Atomic Aborption that we sell undergoes a thorough check and refurbishment process. This process is defined in six categories; Safety, Gas handling, Optics, Electronics, Mechanisms, & Analytical performance. Some of the details are listed below to give a taste of what is involved. This is by no means an exhaustive list.

Safety

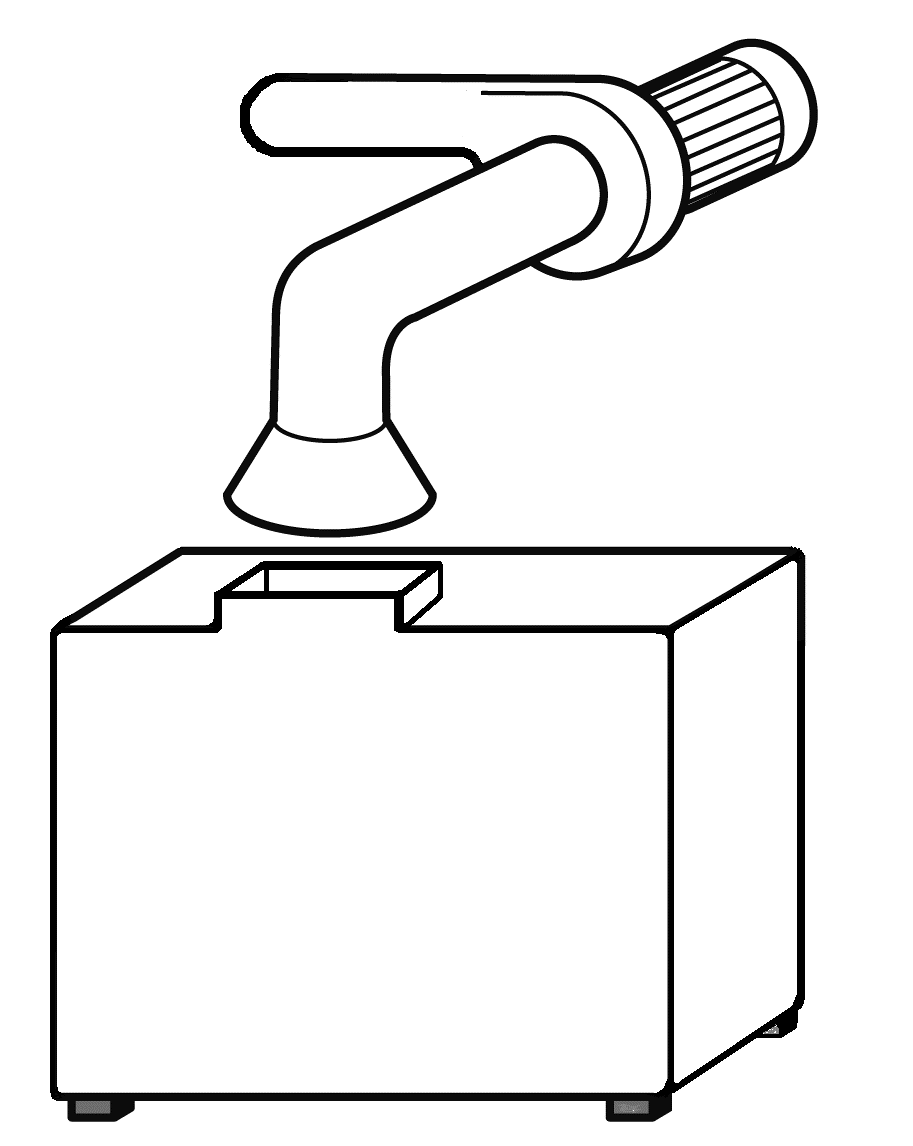

- Change all O-rings and seals in the nebuliser, nebuliser block, spray chamber and burner.

- Check that all interlocks and micro switches function properly.

Gas Handling

- Inspect the spray chamber and its gas connections for leaks.

- Inspect all gas hoses for wear. Leak check all fittings both inside and outside the instrument.

- Check that acetone has not entered the instrument gas manifold.

Optics

- Check that external optical surfaces are clean.

- Using wavelength scan, check that the instrument will calibrate on specific spectral lines.

- Record wavelength accuracy and gain settings. Check D2 performance.

Electronics

- Check all diagnostic LEDs for correct display of instrument function.

- Check power supply voltages, in-built diagnostics, cables, and circuit boards.

Mechanisms

- Exercise solenoids and all motor drives over the full range.

- Check burner adjuster controls.

Analytical Performance

- Run real standard solutions with flame, optimise and report performance.